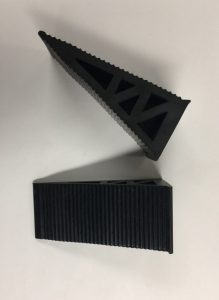

GSH offers state-of-the-art rubber extrusion and fabrication services as well as molded rubber compression and transfer molding services. Whether you need to create a custom prototype or manufacture a line of quality products, you can rely on our designers and engineers to create high quality parts that will meet and exceed your requirements.

We also specialize in 2 axis water jet cutting and CNC plasma cutting of carbon steel. Our engineers have experience in cutting a wide range of sizes and materials to fit a wide variety of applications.

Why Choose GSH Industries as Your OEM Supplier?

A SUPERIOR PRODUCT LINE

Our designers and engineers can assist you in choosing the best materials for your product line. We have a vast selection of materials and can match any custom colors to your customer’s specifications.

ENGINEERING AND CAD DESIGN SUPPORT

Our engineering design team will review your design and give you advice regarding possible material choices, type of process, tooling, and inspection procedures in order to help you design a quality prototype sample. If you need assistance in producing a product line optimized for weathering, impact, or regulatory compliance, our staff can provide you with a wide range of materials as well as in house tooling capabilities.

IN HOUSE TOOLING CAPABILITIES

In order to provide you with a superior end product, we can custom build any of the dies, tools, and specialized equipment that are required to create your product.